Here’s something you must have noticed if you are in the footwear industry: the age-old business practices aren’t as impactful as they used to be. And that means you cannot just design a collection two years in advance, mass-produce it, and hope it leads to success. This approach is falling apart faster than you think, thanks to the digital transformation in the footwear industry.

With the advent and easy adoption of technology across multiple use cases, it has become a prevalent yet very silent shift in the footwear industry. People have figured out why this change is a must and what it will bring, but not how. Everyone is at a different point, some are questioning the need and extent of digital integration, some have already adopted it, and the rest are still debating about it.

But what’s actually pushing this change? A few things, really. Consumers have grown accustomed to personalization in every other category—why should shoes be different? Speed matters more than ever because trends cycle faster than traditional production can handle. And honestly? The economics of overproduction don’t make sense anymore when warehouses full of discounted inventory eat your margins alive.

The opportunity sitting in front of footwear brands right now is genuinely exciting. We’re talking about compressing product development from eighteen months to a few weeks. Offering customization that actually makes money. Cutting waste while improving quality. Reaching customers in ways that felt like science fiction five years ago.

So yes, digital advancements and adoption are a must, and a robust design tool can make it happen. For that to happen, here are a few functionalities that you shouldn’t compromise on when choosing the footwear design tool for your business.

Digital Design Tools

Shorten the product design lifecycle from 3 weeks to a few days. How? With the help of digital design tools.

How Things Used to Work

The offline process consisted of constant back-and-forth between designers and clients. They would send the footwear designs, wait for approvals, make the changes again, and send them for approval. These constant back-and-forths would turn a simple design process into a complicated cycle of design-review-design again.

One style. Months of back-and-forth. Multiply that across a seasonal collection of forty or fifty styles, and you understand why product development timelines stretched into years.

What Modern Design Software Actually Changes

Today’s shoe design software completely alters the whole process. Designers build fully realized 3D models on screen—a detailed representations that show exactly how materials drape, how colors interact, and how proportions balance. Want to see the same design in fifteen different colorways? Takes minutes, not months. Curious how a different sole unit would look? Swap it in and render.

Here’s how it benefits the footwear businesses:

- Design cycles that used to take three weeks now get done in a few days

- Teams spread across three continents collaborate on the same file simultaneously

- Physical samples dropped from ten rounds to two or three (sometimes one)

- Designers experiment freely because trying new ideas costs nothing but time

Budget plays a vital role in designing, and this is where digital tools are exceptionally helpful. When experimenting doesn’t require a physical sample, people shift from “playing safe to maybe this would work better,” which brings a significant shift in the designing quality.

Customization & Personalization

Go from “three color options for you” to “here, build your shoe from scratch” with one simple digital design tool integration.

The Expectation Gap Is Real

People aren’t looking for shoes—they’re hunting for their shoes. Something that matches their vibe. Reflects their personality. Stands out from what everyone else is wearing. The appetite for personalization isn’t new, but the frustration with limited options definitely is.

For years, “customization” in footwear meant choosing between three pre-selected colors. Customers wanted more. But the operational complexity and cost made it difficult for the brands to do that.

How Digital Tools Changed the Math

With the right online shoe design software, customers can configure designs themselves—picking colors, swapping materials, adding patterns, even incorporating personal text or graphics. The system handles the complexity, generates production-ready files automatically, and routes orders without requiring a designer to touch each one.

What this actually unlocks for brands:

- Customers spend more time on your site because they’re creating, not just scrolling

- Conversion rates climb because people buy things they helped design

- Brand loyalty deepens—there’s emotional investment in personalized products

- Inventory risk practically disappears since you’re making what’s already sold

The brands aren’t treating customization as a side project or marketing gimmick. They’ve built it into their core business model. And their profit margins show exactly why that decision made sense.

3D Printing and Rapid Prototyping

Go from multiple design tests, reviews, and waiting for weeks, with one 3D printing and prototyping to accelerate the process.

The Old Timeline Was Brutal

Getting a physical prototype used to mean shipping specs overseas, waiting weeks, paying thousands, and hoping the result matched what you imagined.

Need revisions? Start the clock again. Need multiple variations to compare side-by-side? Multiply everything. 3D printing resolved this gap.

What’s Actually Possible Now

Designers can hold a physical prototype the same afternoon they finalize a digital model. Five variations to evaluate? Print them overnight. The technology particularly shines for midsoles and outsoles, enabling structures that traditional molding simply cannot achieve. All the combinations can be visualized from lattice geometries (for specific cushioning properties) to variable density zones and ventilation channels.

The practical wins brands are reporting:

- Reduction in prototype cost compared to traditional methods

- Material waste is slashed because you’re adding material, not cutting it away

- Design complexity is no longer constrained by what molds can produce

- Small-batch production actually makes financial sense now

Some companies have pushed past prototyping into actual production runs. Custom midsoles printed to individual foot scans? Already happening. Not mainstream yet, but the direction is unmistakable.

Automation & Smart Manufacturing

Witness a significant time reduction in manufacturing the footwear by integrating automated systems for accurate and precise processes.

It Doesn’t Look Like Your Grandfather’s Production Line

A modern footwear facility uses robotic arms to execute precise cuts without needing any human assistance and an automated stitching system to ensure consistency across thousands of units. To add to that, they can also use vision systems to identify defects that human inspectors might miss.

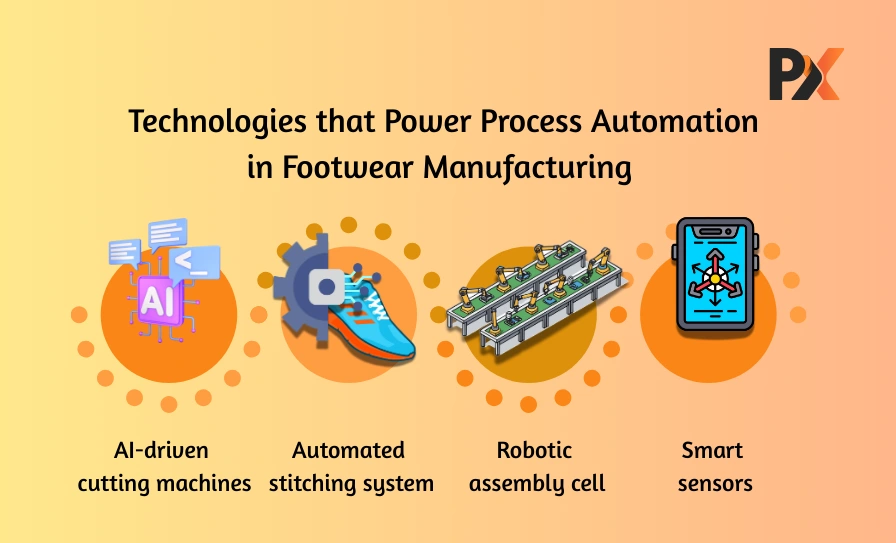

Technologies That Are Actually Making a Difference

- AI-driven cutting machines — Analyze material characteristics and optimize layouts to minimize waste.

- Automated stitching systems — Handle complex patterns at consistent accuracy levels.

- Robotic assembly cells — Execute repetitive tasks without fatigue-related errors.

- Smart sensors everywhere — Monitor glue application temperatures, material tensions, and environmental conditions in real time

This fosters quality consistency that protects brand reputation by accelerating process speed. It is flexible enough to switch between product variations without lengthy changeovers. This differentiates the early adopters from the rest of the businesses.

Virtual Try-Ons & AR Shopping

The most significant change that digital transformation in the footwear industry has brought is virtual try-ons. This will reduce the chances of returns or replacements while improving customer engagement with the latest technology.

Online Shoe Shopping Has an Obvious Weakness

You can’t try them on. Everyone knows this. Returns eat margins. Customers hesitate to order online because of negative past experiences where the photos and product looked nothing like or barely alike. The whole experience carries a risk that physical retail doesn’t have.

Augmented reality addresses this head-on. It lets your customer try on the footwear without actually trying them on. They get to see how the product looks and whether it fits their vibes. No generic rendering, but real-time visualization.

What AR Actually Enables

- Virtual try-on kills purchase anxiety before it stops a sale

- Size recommendation systems analyze foot dimensions through camera input with surprising accuracy

- Interactive experiences keep customers engaged way longer than static product pages ever could

- Social sharing turns shopping into content—customers showing friends potential purchases, basically free marketing

Returns drop when people genuinely understand what they’re ordering. Confidence increases when visualization feels accurate and trustworthy. The technology isn’t flawless yet, but it’s already good enough to meaningfully move conversion metrics. And it keeps improving.

Sustainable Footwear

It is more than just another trend. Sustainability is the need of the hour (and a great marketing strategy). Make your business future-forward with sustainable options.

Sustainability Isn’t Just About Materials

When people talk about sustainable footwear, the conversation usually goes straight to materials. Recycled ocean plastic. Organic cotton. Plant-based leather alternatives. All important stuff, no question.

But digital transformation contributes to sustainability in ways that are often unnoticed. The environmental wins from changing how shoes get made often exceed the impact of changing what they’re made from.

Where Technology Cuts Environmental Impact

- 3D modeling eliminates physical samples — Every sample not produced means materials saved, shipping emissions avoided, and nothing heading to landfill

- AI-optimized cutting patterns — Squeeze maximum usable material from every hide or fabric roll instead of accepting traditional waste rates

- On-demand production models — Make what’s ordered rather than guessing what might sell and overproducing to cover uncertainty

- Digital supply chain visibility — Track carbon footprint at every stage, identify hotspots, and make informed improvement decisions

The waste from traditional footwear production is honestly staggering – sample rounds that get tossed, overproduction that ends up in outlets, or donation bins. Worst of all, material scraps from inefficient cutting.

Digital processes address all of this systematically. The technology side isn’t just about speed and cost anymore—it’s about doing less damage while growing the business.

Where This All Leads: Winners and Everyone Else

Digital transformation in the footwear industry is not an out-of-the-blue thing. Zoom out and the pattern becomes obvious. The footwear industry is sorting itself into two groups: brands embracing digital transformation and brands losing ground because they haven’t.

Companies investing in digital capabilities are reporting:

- Product development timelines compressed 40-60%

- Customer satisfaction climbing as personalization improves

- Production costs dropping through automation and waste elimination

- Sustainability metrics improving without hurting profitability

- Competitive positioning strengthening in markets that keep getting more crowded

None of this is theoretical future-talk. It’s measurable. It’s happening now. Across brands of every size, from startups to industry giants.

The question isn’t whether digital transformation matters for footwear—that debate ended years ago. The real question is how fast your business can implement the tools and processes that make transformation real rather than aspirational.

PrintXpand delivers exactly what footwear brands need to make this shift happen. With powerful shoe design software engineered for customization, real-time 3D visualization, and production system integration that actually works. PrintXpand helps brands offer personalized footwear experiences without the operational nightmares that often come with them. Consumer-facing design tools meet backend workflow automation in a complete package built for modern footwear commerce.

Curious what digital transformation could look like for your footwear business? See what PrintXpand brings to the table.