In the apparel industry, customers love choices. They want to pick colors, fabrics, and styles, especially when it comes to jackets. A leading jacket manufacturer saw this growing demand and wanted to offer customers the freedom to design their own jackets online, while also making its internal work smoother and faster. Along with their ready-made range, the company also wanted to make customization just as simple and accessible. And so, they approached us!

To date, the client and their teams have done everything manually. Each design was created using different tools, and every production update is tracked separately. This made their operations slow and complicated. The company needed a solution that could connect design and production while reducing the need for manual work.

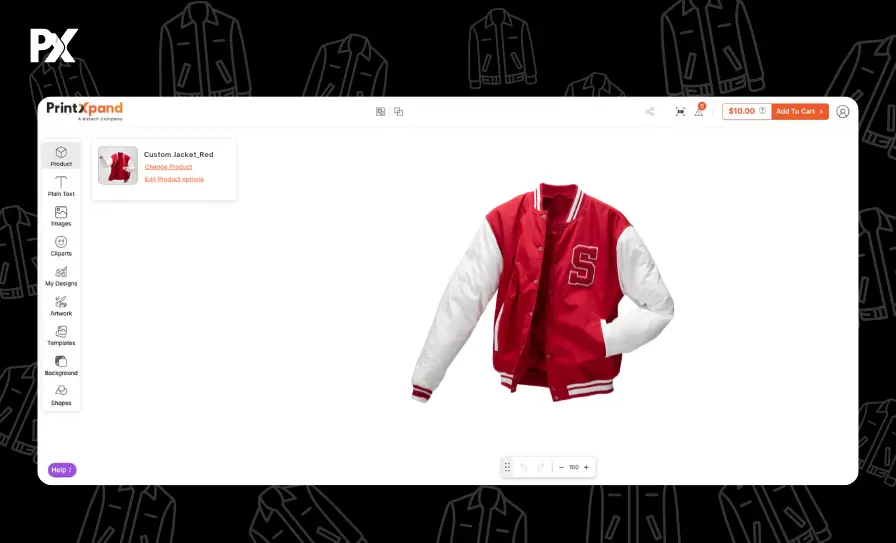

To help them solve these issues, we introduced a solution that any apparel manufacturer can seamlessly integrate into their operations. Our custom jacket design tool lets customers design their jackets online using simple options and live 2D and 3D previews. After a design is ready, it moves straight into the production phase through the integrated ERP for apparel manufacturing. The ERP handles all the information from materials to schedules and employee tasks.

This simple, connected setup works like a complete apparel customization software. And that’s precisely what we offer! An optimized system created by combining an online jacket customization tool with ERP integration, which streamlines operations and enhances customer experience. In short, it is a practical setup that apparel businesses can adopt to save time, lower costs, and deliver customized products faster.

Let’s discuss the issues jacket manufacturers face and how PrintXpand’s “connected setup” can solve them!

The Challenges of Building a Seamless Jacket Design and Production System

We know jacket manufacturers want to make customization simple for their customers and the production process efficient for their employees. However, several challenges stand in the way:

- Customers need a tool that allows them to design jackets online without requiring assistance from the team. The tool must be intuitive and capable of showing real-time design changes.

- Manufacturers need control over customization. Certain design areas cannot be printed or embroidered due to stitching or panel structure, and it’s critical to manage these restrictions.

- A reliable system is necessary on the backend to manage production, inventory, and employee tasks. Without a connected system, departments operate in isolation, leading to inefficiencies.

PrintXpand’s tool allows users to choose fabrics, colors, and styles on the website. The design updates appear in real-time in both 2D and 3D, so customers can see the final product before placing the order.

The system lets manufacturers set clear rules and restrictions within the online jacket customization tool, ensuring that every design is realistic and ready for production.

PrintXpand also implements an ERP for apparel manufacturing that connects departments and keeps everyone updated in real-time. Production teams can track orders, inventory levels adjust automatically, and employees can see their tasks.

Together, these tools form a complete apparel customization software that any jacket manufacturer can implement. It not only supports custom jacket design but also simplifies everyday management, ensuring production and customer experience move hand in hand.

You can implement a system like this as well. Let us show you how easy it can be.

Why Manual Processes Are a Hurdle For the Jacket Manufacturers

If your business relies on manual design and production updates, you may face similar slowdowns that we discussed above.

Without the right solution, every jacket design request that comes through emails or calls can take hours. Additionally, the designers must recreate those ideas from scratch. Some jacket designs can take days to get approved. And sure, you are battling these situations daily, and we know it’s no fun!

Since there isn’t an online jacket customization tool, customers have no way to view their designs or make quick changes instantly. They have to wait for mockups to be shared and approved. This back-and-forth process slows decision-making and reduces customer excitement.

The bigger issue is the lack of connection between design and production. Once a design is approved, it must be manually passed to the production team. There is no single system linking the design files, order details, and material availability. As a result, production teams often face delays or confusion over what to make and when to start.

This manual setup also affects costs. Employees spend most of their time repeating the same tasks — tracking updates, checking materials, and confirming schedules. With no automation or ERP support, errors are common, and productivity suffers.

So, what could you do differently? Well, you can start small, for instance, by introducing a design tool that connects directly to production. Even a partially automated setup helps your teams gain visibility over orders and frees up their time. And once that foundation is in place, scaling with a full apparel customization software becomes much easier.

These challenges make it clear that your business needs an integrated apparel customization software — one that automates design handling, connects with an ERP for apparel manufacturing, and brings speed and accuracy to every order. It is a problem that many apparel businesses face, but one you can easily solve with the right digital system in place.

| Expert Tip: Most manufacturers believe that automation begins with replacing human effort. In reality, it starts with visibility. When you can see where delays happen — whether it’s in design approvals, order handoffs, or inventory updates — that’s when real improvement begins. Take the time to map your current process before implementing any apparel customization software. Understand where you are losing time and data as it will help you design a system that fits your workflow. |

Why PrintXpand’s E-Commerce Platform with Integrated Design and ERP Systems is the Right Solution?

PrintXpand’s solution can be easily implemented and scaled. The aim here is simple — connect the jacket design experience for customers with a production process that runs smoothly in the background.

The solution starts with a custom jacket design tool built into an e-commerce website. Consumers can browse jacket options, make their own designs, and examine the materials with ease. They can also see exactly what they’re ordering before they hit the “place order” button because every tweak they make updates instantly in both 2D and 3D.

The tool also includes smart rules that keep customization within production limits. For example, if a certain panel cannot be printed or embroidered, the system automatically restricts changes in that area. This makes every design practical to manufacture, reducing errors before production even begins.

Pricing is another important feature. The tool comes with a built-in calculator that updates the price of the jacket in real time as and when customers choose different fabrics, colors, or other design features. This simple-looking feature provides transparency and eliminates all the manual price checking!

On the backend, this solution also implements a connected ERP for apparel manufacturing. This system tracks every order from the moment it is placed. It updates material availability, manages production schedules, and assigns tasks to employees automatically. Even the teams can easily avoid overlaps and delays just because they can see their tasks and progress in real time.

With both systems working together, the business runs on a single connected platform — from design to delivery. The apparel customization software makes sure every department stays aligned, and no time is lost between steps.

What’s powerful about this setup is how easily it can be implemented by other apparel manufacturers, too. The online jacket customization tool and ERP integration don’t require complex technical changes. They can be added to existing websites and processes, allowing businesses to start small and grow the system as they expand.

In short, PrintXpand’s solution bridges the gap between creativity and production. It gives customers the freedom to design while giving manufacturers the structure to deliver efficiently — a system any apparel business can implement to modernize how they sell and produce custom jackets.

Looking for a similar solution for your apparel business? Our experts can help you build one that fits your workflow perfectly.

The Impact of Implementing a Connected Solution: Increased Efficiency, Reduced Operational Costs, and Enhanced Customer Experience

After you implement PrintXpand’s solution, the difference gets clearer almost immediately. Your business no longer has to depend on manual design work or back-and-forth communication between departments. What earlier took hours of coordination can now be done in minutes.

With the jacket customization tool, customers can create their own jackets (and yes, without any assistance from your team.) Additionally, they can confidently place orders and make quick edits using the modern 2D and 3D preview features. Once the implementation is complete, design teams can easily focus on creative improvements. So, rather than wasting time on tedious edits, this self-service experience simply increases order accuracy for the business.

You can also notice a big change in how customers respond. The interactive experience makes the entire design process more enjoyable. Customers can see how their jackets look even before confirming an order. This builds trust as well as reduces rework or misunderstanding after delivery.

The real-time pricing feature also turns out to be another game-changer. It provides customers with instant cost updates for every design choice they made. This transparency simplifies decision-making and removes the delays that came from manual price confirmations.

The ERP for apparel manufacturing gives daily operations a structure. Employee tasks get updated on the go, while inventory levels can be monitored in real time, and orders are automatically routed to production. This automation reduces manual labor, lowers operating expenses, and accelerates the delivery.

As departments work within the same apparel customization software, collaboration improves. Teams can see where each order stands and plan their work accordingly. The result is better scheduling, faster turnaround times, and more accurate deliveries.

Any apparel manufacturer can easily achieve these results! They can improve operations, minimize errors, and provide their customers with a more seamless, engaging experience just by integrating an ERP system with an online jacket customization tool.

What Happens When Scaling the Business and Expanding Customization Options?

When PrintXpand’s new system is implemented, your business gets all set for growth. You can expand on the solid digital foundation that is established by the integration of a custom jacket design tool and ERP for apparel manufacturing. You can also experiment with new concepts more easily. Additionally, expanding clientele also feels like a breeze because you can grow the business without compromising the quality or workflow.

But the story doesn’t end here!

Growth opens the door to new possibilities. The same apparel customization software can support fresh jacket styles, materials, and unique personalization options. You can now experiment. And the best part? You don’t have to rebuild anything to grow. You can easily add new printing techniques or creative embellishments right into the existing system whenever you’re ready.

The ERP system also lets you grow at your own pace. You can introduce tools like automated invoicing, CRM, or sales analytics to keep everything organized as and when your production grows. These additions simplify daily work as well as help managers plan better, strengthen customer relationships, and maintain financial clarity.

And then there’s the global opportunity. With online customization, distance no longer matters. The combination of a jacket customization tool and a connected ERP allows you to serve customers anywhere in the world with the same speed and precision as local orders.

But the question is, “How can an apparel manufacturer prepare for that kind of growth?”

Take one step at a time! First, spot where you are losing time or where processes are slowing down. Fix that before moving ahead. After you close those gaps, add new modules or features to directly support your growth goals. This type of steady approach will keep your business running efficiently and scalable.

This is a future that any apparel manufacturer can implement. With a scalable digital setup, you can keep improving your customization options, grow confidently, and reach new customers without the chaos that often comes with expansion.

| Expert Tip: Scaling is about finding a better rhythm for the work you already do. Many manufacturers attempt to grow too quickly, ultimately stretching their teams. Take a moment to look at your data. See how customers utilize the jacket customization tool and how your production team manages orders during peak periods. The patterns will reveal where the real issues lie. Fix those first. When growth comes from understanding, it becomes smoother, more stable, and easier to maintain. |

Ready to Transform Your Apparel Business?

You’ve seen how PrintXpand helps jacket manufacturers, just like you, simplify customization, streamline production, and grow with confidence. The impacts that we have discussed can be achieved by any apparel brand that’s ready to take the next step.

Are you looking for a similar solution for your apparel business? Get a personalized setup designed by our experts and see how easily you can bring efficiency, accuracy, and creativity together — all in one platform.