It’s 9 AM. Three quote requests already. Five artwork approvals are stuck somewhere in email purgatory. One rush order that needs to ship by noon. And your production guys? Still debating which job hits which press first. Sound familiar?

Running a print shop in the current age feels like juggling flaming torches while riding a unicycle. Margins are thinner than ever. Customers expect next-day turnarounds. And somehow, you’re supposed to manage all this with spreadsheets and sticky notes?

The old methods had their time. But that time’s passed. Today’s print operations need something that actually keeps up. That’s where Print ERP comes in. Not another generic business tool, but an actual software built for how your print shops work.

What Print ERP Actually Does?

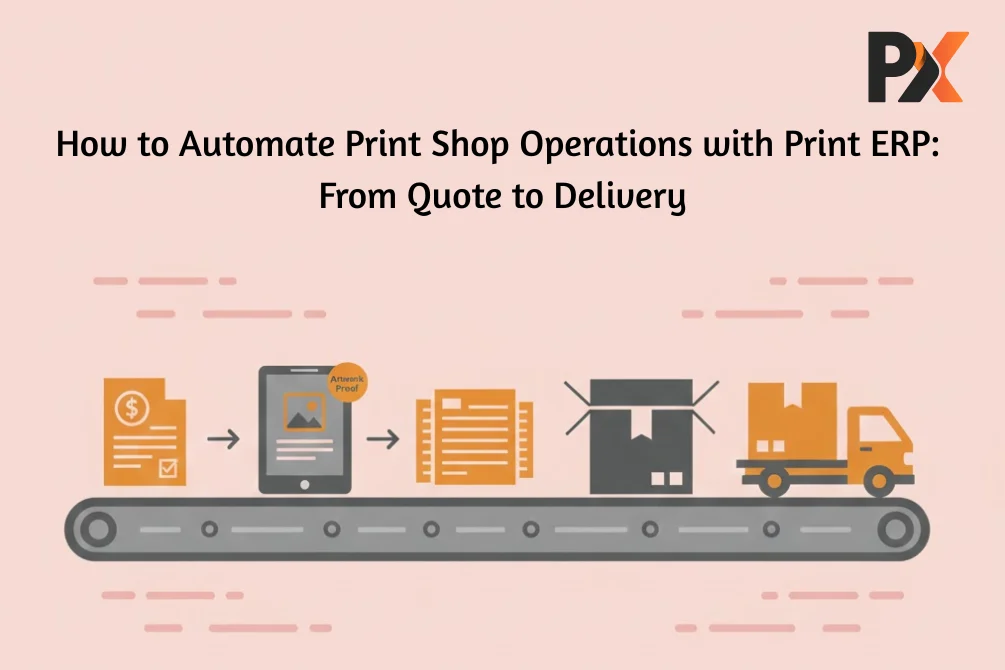

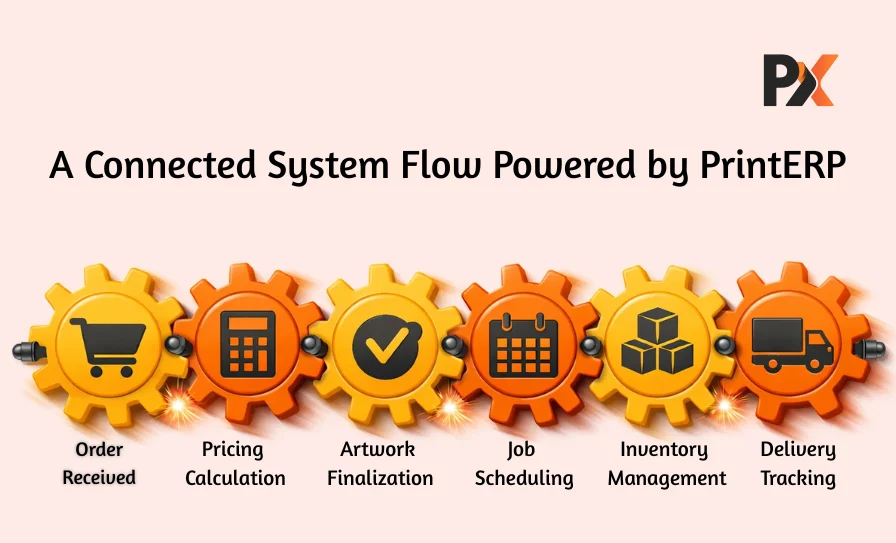

Here’s the simple version: Print ERP connects your web-to-print storefront to everything happening behind the scenes. Orders, estimating, proofing, production scheduling, inventory, shipping — all talking to each other in an end-to-end print automation system.

Think about how disconnected most print shops operate. Customer places an order on your website. Someone manually enters those details into a production sheet. Another person checks inventory in a different system. Scheduling happens on a whiteboard or shared spreadsheet. Shipping info lives somewhere else entirely.

Every handoff is a chance for errors. Every manual entry eats time. Every disconnected system creates blind spots. Print ERP eliminates those gaps. One order entry. One source of truth. Everyone sees the same information.

The system handles:

- Pricing calculations that update automatically based on materials, quantity, and finishing options

- Artwork proofing where customers upload a file, and system checks before it reaches your team

- Job scheduling based on actual machine availability, not guesswork

- Inventory alerts before you run out of critical materials mid-job

- Delivery tracking so customers stop calling to ask where their order is

Everything flows seamlessly and that’s the point.

Quoting Jobs in Minutes, Not Hours

Be honest, how long does your team spend on quotes? An hour or two per complex job? More?

Most shops still do this the hard way. Pull up old invoices for reference. Manually calculate paper costs. Check with production about timing. Format it all into something presentable. Send it off and hope you didn’t underprice yourself.

And here’s the thing, after all that work, maybe half those quotes actually convert. That’s hours of effort walking out the door every week. Print ERP flips this completely.

You configure your pricing rules once. Material costs, labor rates, machine time, margins, all of it on one system. Volume discounts are built right in. Setup fees, finishing charges, rush premiums, everything. The system knows your pricing logic inside out.

After that? The system does the math instantly. So for instance,

Customer selects 1,000 tri-fold brochures, 300 GSM gloss, full color. Before they’ve finished their coffee, a PDF quote hits their inbox. Accurate pricing. Professional format. Zero manual work on your end. Change the quantity to 5,000? New quote regenerates automatically. Different paper stock? Recalculated in seconds.

Your sales team stops being calculators and starts actually selling. They follow up on quotes, build relationships, and close deals. The grunt work disappears.

Fixing the Artwork Nightmare

You know the drill. Customer emails a file. It’s RGB with no bleed. You email back. They send a “fixed” version three days later. Still wrong. More emails. By the time you get something usable, you’re already behind schedule, and everyone’s irritated.

Multiply this by twenty jobs a week. That’s not a minor inconvenience but a massive time sink dragging down your entire operation. This whole mess disappears with proper ERP integration.

Customers upload artwork during checkout. The system automatically checks resolution, color mode, bleed, file format — everything. Problems get flagged immediately, before the order even submits. Customer sees exactly what’s wrong and can fix it right there.

No waiting for your team to review. No sending emails explaining technical requirements for the hundredth time. The system handles that conversation for you.

Once files pass the technical checks, customers see a preview and approve right there. Annotations, revision requests, and final sign-off — all handled in the system. Complete version history, too. No more “which file was the approved one?” confusion.

Your prepress team stops playing email tag and focuses on actual production work. Jobs move from order to press faster. Customers get their stuff sooner. Everyone wins.

Scheduling That Doesn’t Fall Apart

I’ve seen shops running production schedules on whiteboards. Magnets for different machines. Handwritten notes about rush jobs. Works fine until someone forgets to update it and you’ve double-booked your main press.

Or worse — a rush job comes in, someone shuffles the board around, and now three other jobs are delayed without anyone realizing until it’s too late. Print ERP treats scheduling like the complex puzzle it actually is.

Job gets approved? The system checks the type of work, which machines can handle it, the current workload across your floor, and when the customer needs delivery. Then it slots the job automatically.

But it doesn’t just drop jobs randomly. The scheduling logic considers setup times between jobs. It batches similar work together when possible. It knows which operators are certified on which equipment. Rush jobs get flagged and prioritized without blowing up the rest of the schedule.

Your ops team sees real dashboards. What’s pending? Which machines are overloaded? Where bottlenecks are forming, when something needs to shift, you can see exactly what that affects downstream.

You can always drag and drop to reschedule if needed. The system recalculates everything else automatically. Fewer missed deadlines. Less scrambling. People actually know what they’re supposed to work on today.

Stop Running Out of Materials

Nothing kills momentum like discovering you’re short on stock halfway through a job. Suddenly, that 5,000-piece run is delayed, the customer’s frustrated, and you’re paying rush prices to source materials.

Happened once? Annoying. Happens regularly? You’ve got a systemic problem eating into your margins. Print ERP tracks inventory against actual job consumption. Not estimates but real usage data.

Every job that runs pulls from your stock counts. The system knows exactly how much 300 GSM gloss you used on Tuesday’s brochure run. How much cyan ink went into the banner job? Which finishing materials were consumed? Stock levels update as jobs run.

Hit your minimum threshold on any material, and you get alerts before it becomes a crisis. Not after you’ve already promised a delivery date you can’t hit. Connect your suppliers’ price lists, and reordering takes seconds instead of phone calls. See pricing across vendors. Generate POs directly from the system. Track what’s on order and when it’s arriving.

For shops juggling dozens of different substrates and specialty materials, this kind of visibility changes everything. Less waste from over-ordering. Fewer emergency purchases at premium prices. Actual cost control instead of guessing.

Delivery Without the Chaos

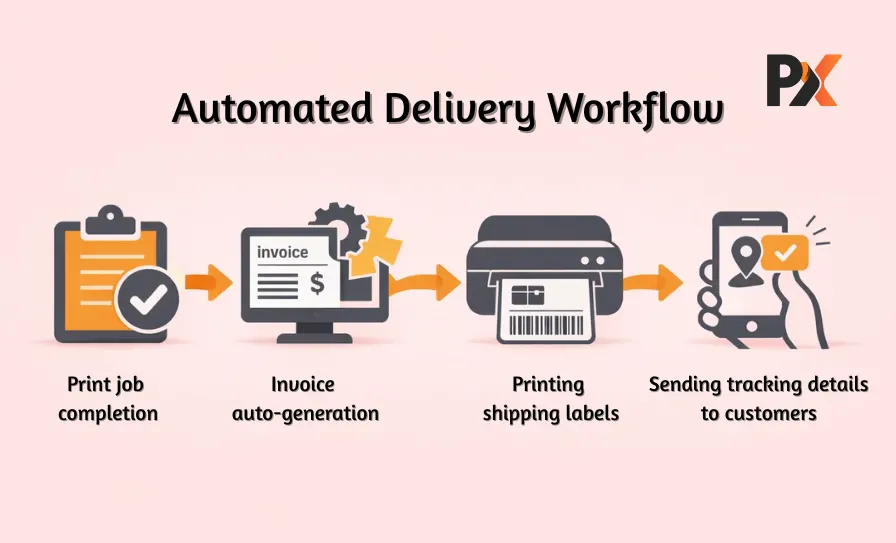

Job’s done. Now what?

In too many shops, this final stretch goes weirdly manual. Invoices in one system. Shipping labels somewhere else. Customer emails… maybe, if someone remembers.

And that last mile matters more than people think. You can nail everything else — perfect print quality, on-time production — but fumble the delivery communication, and that’s what the customer remembers.

Print ERP ties this together automatically. Job completes, invoice generates. Shipping labels are created through your courier integration. Customers get tracking info without anyone having to lift a finger. They know exactly when to expect their order. No anxious emails. No phone calls are tying up your team. Just smooth, professional communication that happens on its own.

People expect to know where their stuff is. Amazon trained everyone to want real-time tracking. When you deliver that automatically, you look professional, and your phone stops ringing with “where’s my order?” calls.

Why PrintXpand Fits Print Businesses

PrintXpand built its web-to-print ERP solution specifically for print businesses. Dynamic estimation, automated proofing, intelligent scheduling, inventory tracking, and delivery management — designed to work together from day one. This isn’t generic software with a printing skin slapped on top. It’s built around how print production actually flows.

A few things worth noting:

The pricing engine handles complex calculations the way print shops actually price jobs. Multiple pricing methods. Quantity breaks that make sense for your business. Not some generic formula that sort of works.

Dashboards show what production teams actually need — pending work, machine status, deadlines, and problems forming. Not vanity metrics. Useful information people will actually check. It integrates with Magento, Shopify, and WooCommerce. You’re not stuck with a proprietary storefront nobody’s heard of. Keep your existing ecommerce setup. Let PrintXpand handle the backend complexity.

Scales from single locations to multi-region print-on-demand operations. The system adapts to you, not the other way around. Start with what you need. Add capabilities as you grow.

Wrapping Up

Print shops have gotten more complicated and customer expectations keep climbing. The manual approach that worked ten years ago? It’s holding you back now. Print ERP brings everything under one roof. Faster quotes. Smoother proofing. Smarter scheduling. Fewer stockouts. Happier customers.

It is not magic, just connected systems doing what they should’ve been doing all along. If you’re spending half your day on stuff that should happen automatically, it’s time to look at what’s possible.

Want to see PrintXpand in action for your setup?