Running a print shop without a pulse on your operations is a bold choice. It is essentially professional gambling. One minute, a job vanishes into the production abyss. Next, a quote is sent out that barely covers the cost of the ink. Tracking jobs manually feels like herding caffeinated cats in a dark room.

Most schedules are just hopeful works of fiction. Cost control usually involves crossing fingers and praying the bank account stays green. This chaotic circus is why printing MIS systems exist. These systems act as the central nervous system for a business that actually wants to turn a profit. Transitioning to a proper MIS means finally trading the “guess and stress” method for actual data.

It is the only way to stop burning money on avoidable errors. Nobody wins a gold medal for being the busiest person in a failing shop. Stop playing hide-and-seek with your margins and get a backbone.

What Is a Printing MIS System?

A printing MIS system is essentially the brain that your shop likely lacks on its most chaotic days. Think of it as an all-seeing eye that stops the bleeding in your bottom line. It manages the entire mess from quoting to the final invoice without breaking a sweat.

Quoting no longer relies on a sales rep’s gut feeling or a lucky coin flip. Job costing becomes a cold, hard reality check instead of a work of creative fiction. The software handles scheduling so the production floor stops looking like a panicked riot. Inventory tracking ensures you aren’t discovering a paper shortage five minutes before a massive run.

The billing procedure gets done immediately instead of lying in a dusty “to-do” list for three weeks. Workflow automation incorporates these slack ends and makes them into a strong knot. The utilization of these systems is the only way to survive in this ruthless industry.

It converts an unorganized bunch of costly machines into a cooperated, profit-making monster. Stop flying blind and start using a system that actually pays for itself.

Key Components of a Printing MIS System

A robust MIS isn’t just a single tool, but a collection of specialized modules designed to handle every moving part of your production floor.

Job Onboarding & Quoting

Sales teams often pull numbers out of thin air while hoping for the best. This component kills that guesswork by creating quotes based on actual capacity and labor. It moves jobs from the “maybe” pile to the production line with zero friction. Stop letting profitable leads die in a cluttered inbox.

Estimation & Costing

Generic pricing is a fast track to bankruptcy in this industry. Accurate estimation looks at every drop of ink and every second of machine time. It reveals which jobs are actually paying the bills and which are just expensive hobbies. If you aren’t counting pennies, you are losing dollars.

Production Scheduling

Most print floors operate on a “whoever yells loudest” priority system. Modern printing MIS systems replace that loudmouth with a logical, automated calendar. It aligns machine availability with delivery dates to prevent a total meltdown. Keeping the presses rolling should not require a miracle every Tuesday.

Inventory & Material Management

Running out of substrate mid-run is a special kind of professional nightmare. This module tracks stock levels in real time, so nobody has to go on a scavenger hunt through the warehouse. It stops the bleeding caused by over-ordering or emergency last-minute shipping fees.

Shipping & Billing Automation

Finishing the job is pointless if the invoice gets lost in the mail. Automated billing ensures you get paid before the client forgets who you are. Shipping integration handles the logistics without the usual manual entry errors that send packages to the wrong continent.

Reporting & Analytics

Data is the only thing standing between a smart strategy and a total shot in the dark. Detailed reports show exactly where the bottlenecks are hiding. Analyze these metrics to see the cold reality of your shop’s performance. Facts do not care about your feelings, but they do help you stay profitable.

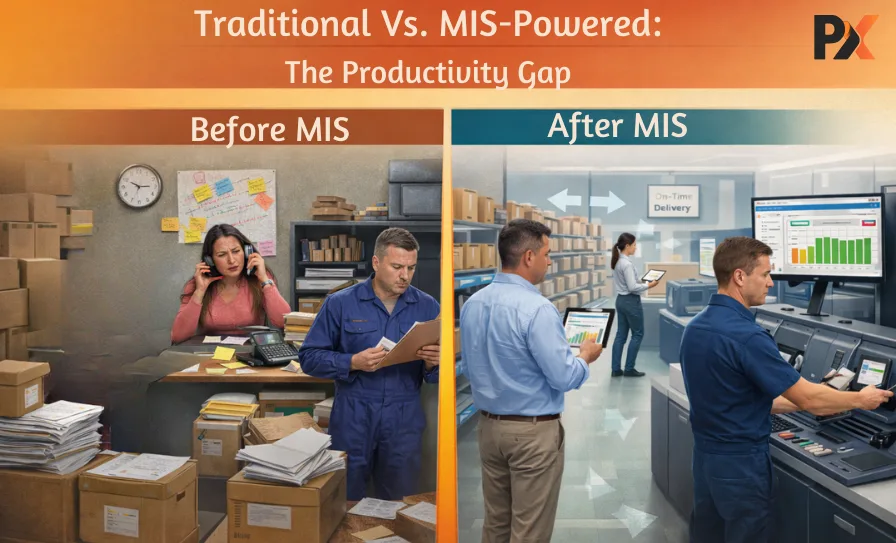

Traditional Print Management vs. Printing MIS Systems

| Feature | Traditional Management (The “Dark Ages”) | Printing MIS Systems (The Modern Backbone) |

| Data Entry | Manual spreadsheets prone to “fat-finger” typos and lost files. | Single-entry automation that flows through the entire shop. |

| Quoting | Sales reps using “gut feelings” or outdated price lists. | Data-driven estimates based on real-time material costs. |

| Job Tracking | Physical job jackets that vanish into thin air. | Real-time digital dashboards accessible from anywhere. |

| Scheduling | A whiteboard that stays accurate for approximately five minutes. | Dynamic scheduling that adjusts as new orders arrive. |

| Inventory | Scavenger hunts in the warehouse to see if paper exists. | Automatic stock alerts that prevent “out-of-stock” panics. |

| Communication | Endless internal emails and “did you get my text?” chains. | Centralized notes and automated triggers for every team. |

| Error Rate | “Oops, I printed the wrong color” happens once a week. | Validation checks that kill errors before they hit the press. |

How Printing MIS Systems Streamline Print Shop Operations?

Implementing an MIS transforms your shop from a collection of isolated tasks into a fluid, high-speed operation by removing the manual friction that slows you down.

Automated Estimates

Manual quoting is a relic of the past that belongs in a museum. Relying on a sales rep to scribble numbers on a napkin is asking for a financial disaster. These systems calculate costs based on actual ink usage and labor rates instantly.

You finally get to stop leaving money on the table because of a math error. It is time to put the calculator down and let the software handle the heavy lifting.

Optimized Job Routing

Sending a job to the wrong press is an expensive way to ruin a morning. Smart routing ensures every project takes the path of least resistance through the facility. It accounts for machine capabilities and current finishing bottlenecks without requiring a staff meeting. Efficiency is the name of the game when deadlines are breathing down your neck. Do not let a simple task turn into a logistical nightmare.

Real-Time Machine Load Visibility

Flying blind is fine for bats, but terrible for running a multi-million dollar print floor. Visibility means knowing exactly which press is idling and which is slammed before the backlogs start. You can spot a train wreck coming from a mile away and pivot accordingly. This transparency prevents the “all hands on deck” panic that kills employee morale. Stop guessing when the work will be done and start knowing.

Reduced Miscommunication

Playing a game of “telephone” with client specifications is a recipe for a massive reprint. Centralized data means the prepress team actually sees what the customer ordered. There are no more excuses about missing emails or misinterpreted handwritten notes. When everyone is on the same page, the finger-pointing finally stops. Clear instructions are the only way to keep the peace in a busy shop.

Faster Production Timelines

Speed is great, but controlled speed is what actually generates a healthy profit. Trimming the fat from your workflow allows jobs to fly out the door ahead of schedule. Printing MIS systems remove the manual speed bumps that keep your production team stuck in second gear. You can handle a higher volume of work without hiring an army of new coordinators. Turn your shop into a well-oiled machine that actually hits its targets.

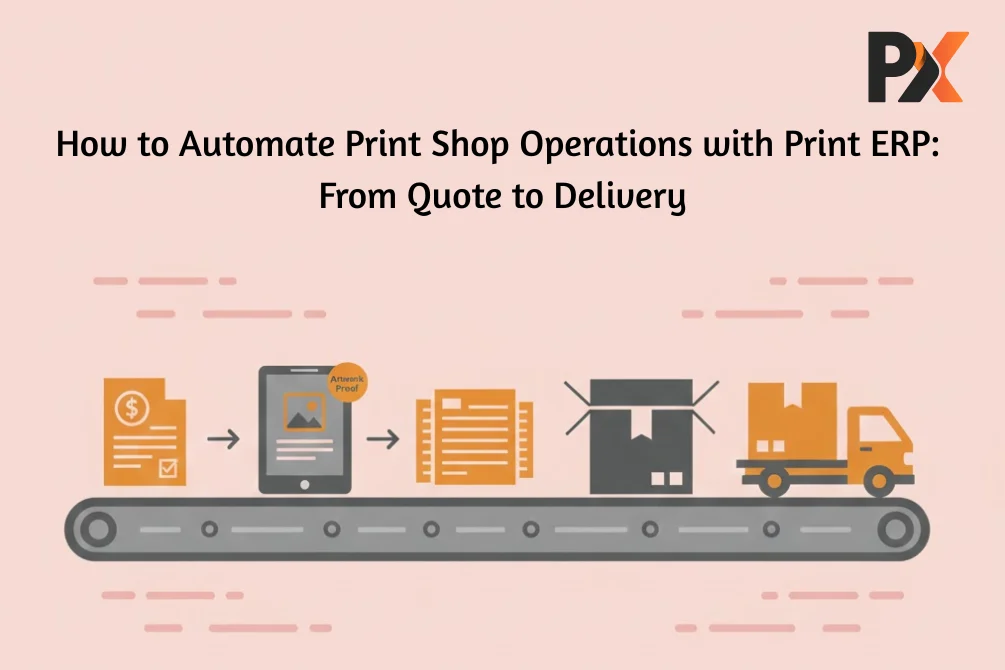

Integrating Printing MIS with Web-to-Print Platforms

Marrying your online storefront with your back-end operations is the only way to escape the manual entry purgatory. When online ordering talks directly to printing MIS systems, the magic actually starts to happen.

A customer places an order and the system creates the job ticket without a human needing to touch a single key. This stops the endless cycle of babysitting orders that should have been automated years ago. The production workflow kicks in immediately because the data is already where it needs to be. No more waiting for a tired coordinator to wake up and move a file from one folder to another.

Shipping labels practically generate themselves once the press stops spinning. This complete process assures that the left hand at last knows what the right hand is doing. It changes a disorganized chaos into a modern factory that operates while everyone else is awake.

If the objective is to stop behaving like a fancy computer operator, this merger is the magic key. Do not resist the future and let the computer handle the dirty work.

Business Benefits of Implementing a Printing MIS System

Beyond just organizing your day-to-day tasks, a professional MIS delivers a measurable impact on your bottom line by turning hidden operational leaks into visible profits.

Cost Accuracy

Standardizing your pricing is the only way to stop bleeding cash on every complex order. Printing MIS systems calculate every cent of overhead so the house always wins. Stop letting estimated costs be a shot in the dark that misses the target. Real accuracy means knowing exactly how much you spent on that rush job before it leaves the dock.

Production Efficiency

Most shops are running like a headless chicken because they lack a central brain. Automation removes the friction that keeps your best machines sitting idle for no reason. It streamlines the flow from prepress to finishing without requiring a miracle or a bribe. Stop working harder when you could simply work smarter by cutting out the useless fluff.

Profit Margins

Revenue is just a vanity metric if your actual take-home pay is microscopic. These systems highlight which clients are actually profitable and which ones are just wasting your time. You can finally prune the dead wood and focus on work that keeps the lights on. Watch the bottom line grow once the hidden leaks in your production are finally plugged.

Customer Experience

Clients do not care about your internal struggles or why a job is three days late. They want their orders correct and delivered on time without having to beg for an update. A professional system provides the transparency that builds real trust and repeat business. Delivering excellence consistently is the best marketing strategy money can buy.

Reduced Human Error

Tired employees make expensive mistakes that turn your profit into scrap paper. Manual data entry is a ticking time bomb that eventually destroys a high-value project. Centralizing information ensures the press operator isn’t guessing which version of the file is the final one. Kill the “oops” factor before it kills your reputation in this cutthroat market.

How to Choose the Right Printing MIS System for Your Business?

Selecting the right system is a high-stakes decision that requires balancing your current operational needs with your long-term goals for growth and technical stability.

Cloud Vs On-Premise

Deciding between a dusty server in a closet and a cloud platform is a major crossroads. Maintaining physical hardware is a full-time job that usually ends in a painful data crash. Cloud-based printing MIS systems offer access from anywhere without the constant fear of a local power outage. Pick a solution that does not require an IT degree just to keep the lights on.

Features Needed Based On Business Size

Purchasing a huge system for a tiny workshop is like using a big hammer to kill a little bug. Complicating a process with non-essential features and functions just irritates the workers and wastes their time. Adjust the tools to the real amount of work that is going through the plant. Do not pay for a multitude of features that will only gather digital dust on a dashboard.

Integration With Web-To-Print

A system that operates in isolation wastes your money completely. The software has to be integrated with your online selling platform to avoid manual data entry horrors. True automation occurs when the end-user does the work of the manufacturer. Make sure the puzzle’s pieces really fit before you sign a long-term lease.

Scalability

Planning for the future means choosing a system that will not break when volume doubles. Switching software every two years is an expensive exercise in frustration. The platform should grow at the same pace as the revenue without requiring a total overhaul. Do not get stuck in a digital dead end because the current choice is too rigid.

User-Friendliness

If the interface looks like a flight simulator from the nineties, your team will hate it. Complex software is only useful if the staff actually wants to use it every day. A steep learning curve leads to shortcuts and more mistakes on the production floor. Keep it simple so everyone can focus on printing rather than troubleshooting a confusing menu.

Reporting Quality

Vague numbers are worse than no numbers because they give a false sense of security. Quality reporting exposes the raw truth about which machines are draining the bank account. It turns a pile of raw data into a clear map for future growth. If the reports are unreadable, the entire system is just an expensive paperweight.

Closing Lines

Sticking to manual processes while the rest of the world moves forward is a slow form of corporate suicide. Relying on luck and a stack of sticky notes will not save a sinking ship. Modern printing MIS systems are the only lifeboats that actually work in this stormy industry.

Continuing to manage a massive facility with spreadsheets is simply asking for a total meltdown. Profitability requires a backbone made of data rather than a wish and a prayer. Every day spent without a proper system is another day of flushing margins down the drain. Real leaders know when to stop digging a hole and start building a skyscraper.

High-volume success is not an accident that happens to people who enjoy chaos. It is the result of choosing the right tools to handle the heavy lifting. Get the house in order before the competition buries it under their faster turnaround times.