Bottle manufacturers are seeing a quick and significant shift in buyer expectations. Businesses now want the freedom to customize bottles the same way they customize their branding instead of choosing from a fixed catalog. They want to select the bottle type in a click, switch cap colors, place their own sticker design, and preview everything online before committing to an order. The challenge is that most manufacturers still handle this through emails, manual mockups, and slow quoting, which creates delays on both sides.

To fix this, bottle manufacturer have to upgrade their process with a digital setup powered by PrintXpand. What is so significant about it? The solution includes a 3D product configurator for bottles, built as an online design tool where customers can personalize every part of the bottle and see the results instantly. It also offers automated price calculation, removing the need for manual quotes.

On the backend, the system connects with a bottle manufacturing ERP system, turning what used to be an offline workflow into a smooth, trackable process. This setup gives manufacturers a smarter way to work with bottle customization software and handle customization without changing their entire workflow.

Why Do Businesses Need A Seamless and Customizable Bottle Design Platform

Once manufacturers decide to move away from manual processes, the first question that comes up is: What should the ideal online customization experience look like for a bottle buyer? Most manufacturers want something that doesn’t feel like a form or a design request, but an actual hands-on tool where customers can build their bottle the way they imagine it.

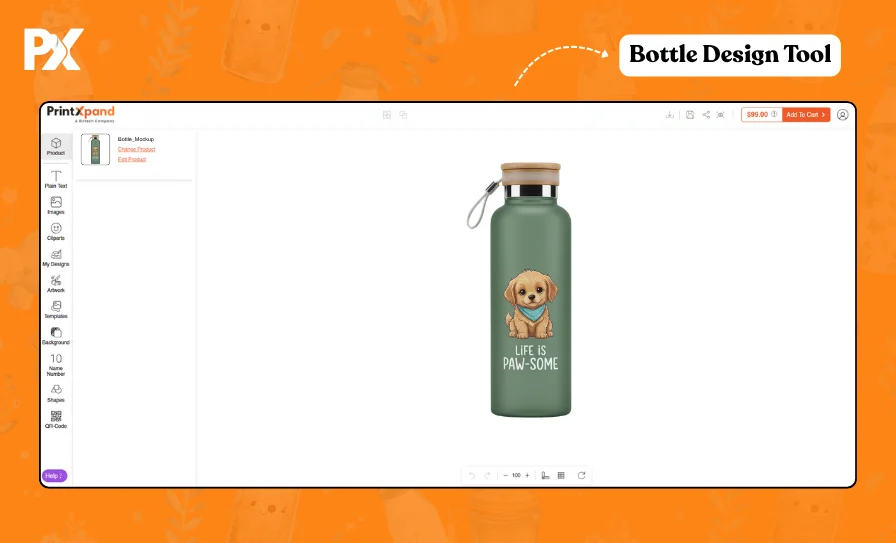

Now that open opportunities for a custom bottle design tool that lets customers choose the bottle style, change the cap, and explore different combinations directly on the website. Instead of sending files back and forth, customers can complete everything inside an online bottle design tool, without needing support from the sales team. No downloads. No email attachments. Just a guided, interactive experience.

Another key requirement that manufacturers may have is of sticker placement. Since most brands care more about how their label looks than the bottle itself, the tool needs to have a way to upload and position sticker designs on the bottle’s surface, exactly where they would appear in real life.

And then there is pricing. Every change in bottle type, color, or sticker area affects the cost, which previously had to be calculated manually. So the tool should also have its own built-in pricing logic that updates totals instantly, without involving a salesperson.

Lastly, everything needs to connect with the manufacturer’s existing e-commerce system so customers can finalize the order as soon as they finish designing.

In one line, bottle manufacturers are not asking for a configurator. They want a 3D product configurator for bottles that combines customization, sticker design, automated pricing, and checkout — all in one smooth flow.

What Growth Barriers Do Manual Processes Create for Bottle Manufacturers

Working with manual processes means every custom bottle request has to pass through multiple people. A customer would explain what they wanted, and the design team would create a visual and send it back. Then the team would wait for feedback, make changes, re-send the file, and only after all, they move forward. It often takes days, sometimes longer, to complete what should have been a simple request. Not because the team is slow — just because every step depends on someone manually updating something.

At this point, a natural question many manufacturers ask is, “Why do these delays feel even bigger as the business starts growing?” That is because, as inquiries increase, the number of touchpoints grows with them. Every new variation, customer request, or revision adds more manual work without adding more time, turning what once felt manageable into a daily bottleneck.

Even customers cannot see the bottle themselves, so even small decisions like cap color or label size are turned into long email threads. Without a live preview, most people delay approval because they weren’t fully confident in what they were ordering.

Pricing caused the same kind of slowdown. Every variation — bottle type, material, sticker area — has to be calculated by hand. One small update meant redoing the quote, which opens the door to mistakes and inconsistency.

And when the number of custom requests grows, capacity-related issues start to show up. Manual systems cannot scale because too much depends on human effort instead of a tool that can automate repetitive tasks.

That’s when it becomes clear that your process does not need more people! It needs automation.

See how effortless approvals become when customers can visualize every detail themselves.

How Can PrintXpand Transform Bottle Customization With a 3D Configurator and Automated Pricing Engine

Once the bottleneck gets clear, the urgency to “digitize” the process arises. Manufacturers, regardless of their location, want to give their customers a way to design bottles on their own. Yes, of course, without them having to wait on the sales or design team. Additionally, they want to make sure that the backend stays organized and accurate.

At this stage, you may wonder, “Does shifting so much control to the customer risk overwhelming them with too many choices?” Interestingly, it usually has the opposite effect. When customers see options visually and make changes in real time, decision-making becomes easier, not harder—because they no longer have to imagine the outcome or rely on guesswork.

And so, this is where PrintXpand can step in with their custom-built 3D product configurator for bottles — a tool that can work the way the business already functions, just without the manual workload.

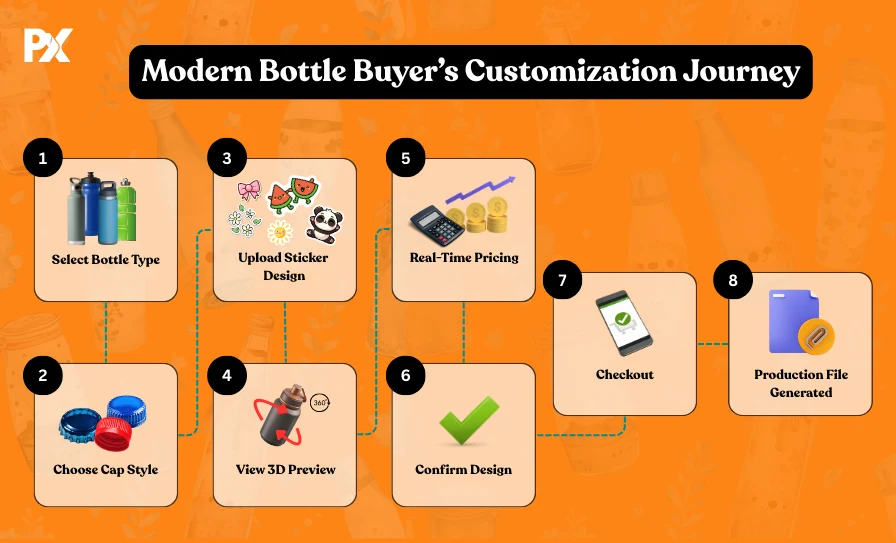

The experience begins on the website, where customers can start customizing right away. They don’t need instructions or training because the configurator works like a guided custom design tool. They simply:

- Select the bottle type (shape, size, material)

- Choose the cap color or style

- Upload or apply their sticker design

- View everything in a live 3D preview

This kind of setup turns the configurator into a complete custom bottle design tool, not just a visual mockup generator. Every change updates instantly on screen. No mockups. No email approvals. No guessing what it will look like after production.

To keep designs realistic and manufacturing-ready, the configurator can be customized with restricted design zones aligned with production specifications. For this, PrintXpand offers two solutions that work in sync with each other

- 3D Design Tool – It defines a customizable space for users to place their stickers. This eliminates the possibility of the design going on curves or seams that the machine can’t handle.

- 3D Configurator – A tool that wraps the design around the model in 3D, which, here, is a bottle. So users can see the design in 3D to get a faint idea of what the final product will look like.

Both tools offer two key functionalities that, when implemented together, can significantly streamline the process and protect both the customer experience and the production team’s resources.

The next big piece is pricing. Instead of waiting for a quote, the configurator can calculate the cost based on whatever the customer selects — bottle type, cap color, sticker size, quantity, and more. This turns manual quoting into an automated pricing engine with built-in pricing logic, and the order total updates in real time. No spreadsheets. No recalculations. No delays.

Once the customer is satisfied with the design and the final price, they can head directly to checkout. And since the configurator is connected through full e-commerce integration, there’s no separate form or manual handoff. Just design, approve, and order.

On the backend, the new backend management system gives the business a single dashboard where they can manage:

- Order management

- Production-ready design files

- Customer specifications

- Pricing rules and updates

So instead of chasing files, clarifying emails, or re-quoting jobs, everything is already captured in one place and ready for production. The tool works as both an online bottle design tool for customers and a backend control panel for the manufacturer, without changing their ERP or rebuilding their workflow.

In the end, what the bottle manufacturers get is not just a configurator. It is a complete bottle customization software setup that handles design, pricing, order flow, and production data automatically — the exact upgrade needed to scale without adding more manual work.

| Expert Tip:

Use the manual save feature as a conversion hook. Logged-in users can save designs and revisit them later, but most customers don’t notice this until it’s too late. Adding a visible ‘Save Your Design’ prompt during customization encourages account creation and gives interrupted shoppers an easy way back. Small nudge, noticeable lift. |

How Can Implementing PrintXpand’s Solution Impact a Business’s Efficiency, Customer Satisfaction, and Operations?

Once the 3D product configurator and backend management system go live, the difference becomes obvious. The design team no longer has to spend half their day recreating mockups or updating quotes. Customers finally have the freedom to personalize their bottles themselves, and that single shift changes how fast orders move through the pipeline.

Here’s what starts happening after the system is implemented:

Faster Design and Order Processing

Because the design and pricing steps are now automated, the team no longer touches orders manually. Customers can choose the bottle, upload their sticker, tweak the cap, and approve the final view on their own. What took days earlier now takes minutes.

Enhanced Customer Engagement

The live 3D preview turns customization into an interactive experience rather than a transaction. Buyers can rotate the bottle, check how the sticker sits, test combinations, and fix things instantly — which naturally leads to fewer revisions and more confident orders.

Consistent Pricing and Transparency

The automated pricing engine removes the guesswork. Every selection updates the cost in real time, so customers see exactly what they’re paying for. No recalculations. No back-and-forth for quotes. No “let me check and get back to you” emails.

Scalability and Efficiency

Bottle manufacturers can handle more custom orders without hiring more people. With the backend management system, everything — designs, order details, specs, and pricing rules — stays organized in one place. And because it connects directly with existing bottle manufacturing ERP systems, teams don’t need to replace or rebuild anything on the operations side.

Streamlined Operations

Since the configurator can tie directly to e-commerce integration and order flow, there’s no manual handoff between design, checkout, and production. The process now feels like a single system instead of five disconnected steps.

Instead of chasing files, updating quotes, or clarifying instructions, teams can now spend time actually running the business. The new setup turns the old manual workflow into a predictable, automated one – a real example of how bottle customization software can support scale instead of slowing it down.

| Expert Tip: Set up a weekly internal review of abandoned designs filtered by bottle type. Patterns here often signal gaps in your product mix—missing sizes, cap styles, or color variations customers are expecting. It’s one of the fastest ways to spot opportunities for new SKUs. |

The Future: Expanding Customization and Enhancing Customer Experience

Now that the core system runs smoothly, bottle manufacturers have room to grow without rebuilding anything. One of the biggest advantages of this setup is that it fully supports expanding product offerings. New bottle types, additional cap variations, seasonal finishes, or even special features like embossed logos can be added to the same configurator as the business evolves.

As the order volume increases, the backend management system can also be upgraded with advanced analytics and reporting. That means the team can track which bottle styles sell most, which customization features customers use, and which price ranges convert better — turning real data into smarter product decisions instead of assumptions.

Additionally, there is room to improve the purchasing experience. With enhanced e-commerce capabilities, your business can introduce multi-currency checkout and global shipping rules. And as you enter new markets, you can also use region-specific pricing. The existing structure already supports scalability. In short, expanding internationally becomes a configuration upgrade rather than a re-platforming project.

Simply put, the 3D product configurator already delivers the customization features bottle manufacturers need today. The backend management system adds the flexibility to grow – whether that means entering new markets, adding more product variations, or using analytics to improve operations and customer experience over time.

Ready to Build a System Like This?

If you want to offer the same self-serve bottle customization experience — and streamline the way your team handles design, pricing, and order management — the team at PX can walk you through it live.

You’ll be able to see how the configurator works on the front end, how pricing automation functions, and how the backend system keeps orders organized without manual follow-ups.