You know the print-on-demand business model by now. Someone creates a funny cat design, throws it on a t-shirt mockup, lists it online, and suddenly they’re shipping custom merch to strangers across the country. No warehouse. No inventory gambles. Just pure print-on-demand magic.

Printful built an empire on this idea. So did Printify, Gooten, and dozens of others.

But here’s what nobody talks about at the entrepreneur meetups: the behind-the-scenes machinery. That slick storefront is just the tip of the iceberg. Underneath sits web-to-print automation — the actual iceberg of machine moving orders from “buy now” click to doorstep delivery. Without it, print on demand solutions fall apart the moment volume picks up. Speed tanks. Errors multiply. Customers bail.

Automation isn’t optional here. It’s the need to stay in the current exhaustingly competitive market.

What Is Web-to-Print Automation?

In very simple terms, web-to-print automation allows your online store to talk directly with your print production. This means software handles everything in between — no human copying order details into spreadsheets, no one manually emailing print files to vendors.

Picture a pipeline. Customer lands on your site, customizes a hoodie with their dog’s face on it, and hits purchase. That order data goes straight through to production. Files get prepped automatically. Job lands in a press queue. Hoodie gets printed, packed, and shipped. Customer gets tracking updates. You can check the progress on your dashboard while automation handles the entire process.

Without it? Totally different story. Someone on your team manually grabs order info. Copies it somewhere else. Opens Photoshop, preps the artwork. Emails files to production. Follow up to confirm they got it. Updates the customer by hand. Rinse and repeat for every single order.

Twenty orders a week? Manual print job is annoying, but doable, make it two hundred? And, you’re drowning.

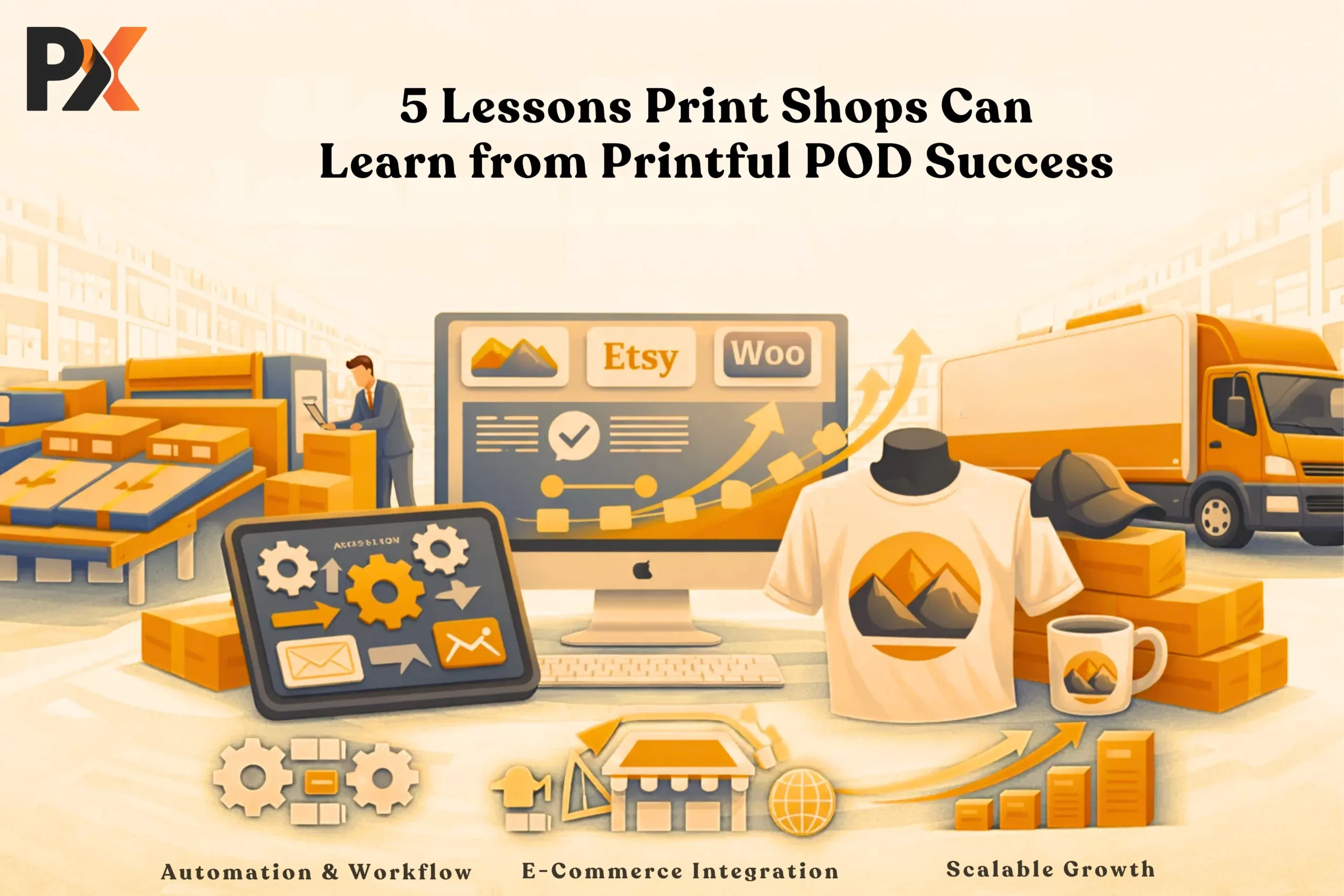

Understanding the Printful-Style Business Model

Printful cracked a code that resonated with creators everywhere: sell custom stuff without the upfront risk.

The mechanics go like this — you take the potential products (tees, mugs, posters, phone cases, whatever), list them on your store, and only produce when someone actually buys. No guessing what’ll sell. No dead stock collecting dust. Just on-demand production triggered by real purchases. The concept is simple, but execution gets messy.

Here’s why. A single t-shirt design in five colors and eight sizes? That’s 40 SKUs from one graphic. Got 50 designs? You’re managing 2,000 variants. And most sellers are running more than one sales channel — they’re juggling Shopify, Etsy, Amazon, maybe a WooCommerce site for good measure. Each platform with its own order format and sync headaches.

Then there’s the customization piece. Modern buyers want to tweak stuff — add their name, change fonts, upload photos. They expect an accurate preview before checkout. And whatever they see on screen better match what arrives in the mail, or you’re adding refunds to your expenses and one-star reviews on the platform.

Speed pressure compounds everything. People shopping these platforms compare your shipping times against giants like Amazon. Not fair, but that’s reality. Slow turnaround kills your search ranking and repeat business.

And to top it all off, try running all this on Google Sheets and email threads, spoiler alert? It doesn’t work. To scale a printful-style business, you need proper digital infrastructure powered by dedicated print on demand solutions.

Why Manual Processes Break POD Businesses at Scale

When you’re processing a handful of orders daily, manual workflows feel fine. Tedious but manageable. Increase the volume, and the whole system will reach its breaking point.

Order mistakes become constant. Copy-paste errors sneak in everywhere — wrong size, wrong color, misspelled personalization. Half these errors ship before anyone catches them. The other half gets caught late and goes back for reprinting. Either way, you lose money.

Artwork prep turns into a chokepoint. Someone’s gotta convert customer files into print-ready formats. Check resolution. Fix color profiles. Position graphics correctly. That person becomes your bottleneck. Orders stack up while they wait on them, and customers wonder why production’s taking so long.

Communication gets messy fast. Specs traveling through email chains? Things get lost. Outdated info reaches production. Change requests never make it to the floor. Nobody’s sure which file version is current.

Tracking becomes chaos. Customer asks where their order is. You have no clue. You’re digging through emails and spreadsheets trying to piece together status updates.

And the costs? They compound viciously. Reprints aren’t free. Neither are refunds. Or expedited shipping to fix delays. Most print on demand solutions run tight margins already. A few percentage points in error rates can wipe out profitability entirely.

Customer trust disappears too. One wrong order, maybe they forgive you. Two? They’re leaving reviews. Three? Chargebacks and gone forever.

The fundamental issue: manual processes don’t scale gracefully. Double your orders and your problems more than double. And print on demand business live or die by their ability to scale. Growth becomes a trap instead of a reward.

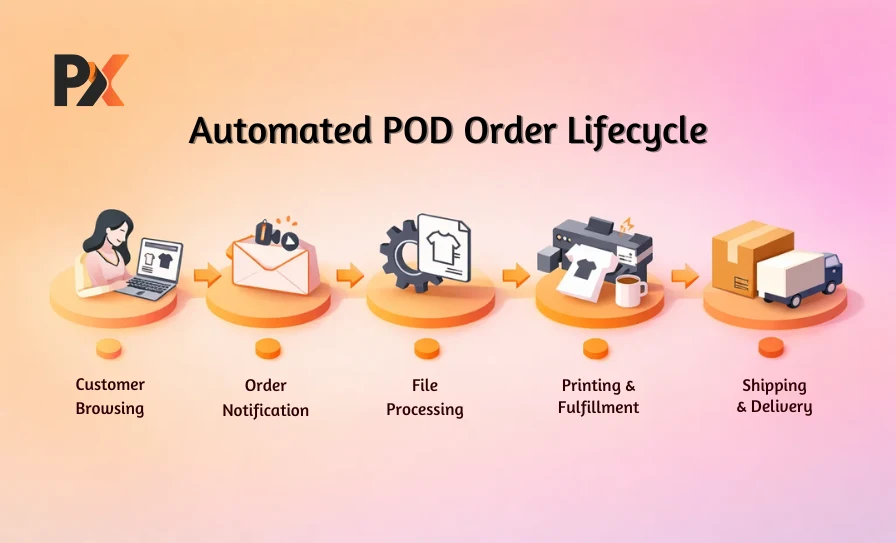

How Web-to-Print Automation Powers Every Stage of a POD Business

Automation doesn’t just patch one hole, it transforms the entire order journey. Here’s how print on demand solutions benefit at each stage.

Product setup gets way faster. Creating new products used to mean hours of mockup work, photography, variant setup, and description writing. Automation tools compress all that. So your business can bulk upload designs, auto-generate mockups, and push products live in minutes instead of days. Your catalog grows without your workload growing proportionally.

Customer customization actually works. Browser-based design tools let buyers personalize products without needing a designer. They add text, upload images, and swap colors, and the software validates everything in real time. No back-and-forth about file resolution. No “that image won’t print well” emails. What they design matches what they get.

Orders flow straight to production. This is the big one. Order comes in, system captures specs, artwork processes automatically, files convert to print-ready formats, job routes to the right production queue. No human touches it unless something’s flagged for review. Purchase to production-ready in minutes or hours, not days and weeks.

Exceptions get handled systematically. Not every order is standard. Rush requests, specialty products, and artwork issues require different process rules, and automation platforms let you define them. Flag orders needing manual review. Route wide-format jobs to specific vendors. Send alerts when something needs attention. Exceptions become manageable instead of overwhelming.

Fulfillment and tracking sync on their own. Production finishes, label generates, tracking pushes to customers, everything happens in a connected workflow. Buyers know where their stuff is without your team having to send individual updates.

The payoff? Volume stops being scary. Five hundred orders feel manageable with the same team that used to buckle under fifty.

Key Automation Features Every Printful-Style Business Needs

Shopping for print on demand solutions or building your own stack? These features separate systems that work from ones that frustrate:

Online product designer: Browser-based, letting customers personalize with text, graphics, images, and colors. Has to feel intuitive for people who’ve never touched design software. Preview accuracy is non-negotiable.

Automated order flow: Orders moving from the storefront to production without manual intervention. Captures specs, processes files, and assigns jobs. Humans only step in for exceptions.

Print-ready file generation: Automatic conversion handling, resolution checks, color profiles, bleed setup, and proper naming conventions. No one is manually prepping artwork for every order.

Multi-store integration: Connections pulling orders from Shopify, WooCommerce, Etsy, Amazon, wherever you sell. Everything is funneling into one system instead of being scattered across platforms.

Centralized dashboard: Single view across all channels, all orders, all statuses. Filterable. Real-time. Visibility for your team and, optionally, for customers tracking shipments.

Vendor management: If you’re working with multiple printers or fulfillment partners, jobs should route intelligently based on product type, geography, capacity, and cost.

These aren’t premium upgrades. For print on demand solutions running any serious volume, they’re baseline requirements.

How PrintXpand Enables Web-to-Print Automation for Printful-Like Businesses

PrintXpand doesn’t just offer tools; it provides the foundation for building your own Printful-style operation from scratch.

The platform covers end-to-end web-to-print automation. Customer-facing product designer, backend order processing, automatic artwork generation, and production routing, everything is and stays connected. Orders flow from the storefront to fulfillment without manual handoffs that clog the pipeline.

Want to launch your own POD marketplace? PrintXpand handles that infrastructure too. Multi-seller onboarding brings vendors onto your platform, each managing their own products while you maintain centralized control. Revenue sharing models, catalog management, and fulfillment rules, all built in rather than bolted on.

The integration capabilities span major eCommerce platforms. Shopify, WooCommerce, Magento, PrestaShop — orders from connected stores sync into one dashboard. No more tab-juggling or spreadsheet reconciliation.

Custom workflows accommodate the complexity that generic solutions ignore. PrintXpand understands that different product types following different production paths. So specialty items get routed to specialty vendors. Rush jobs are flagged automatically. The system bends to match how your operation actually runs.

For anyone who wants to expand their print business, PrintXpand’s print on demand solutions deliver the automation backbone that makes real growth possible.

Conclusion

From the outside, Printful-style businesses look effortless. Just mugs and t-shirts flowing to happy customers. But underneath? Pure orchestration. Thousands of moving pieces syncing across storefronts, design tools, production floors, and shipping carriers.

Web-to-print automation makes that orchestration possible. Without it, you’re stuck firefighting instead of scaling.

PrintXpand offers the print on demand solutions infrastructure — complete automation, marketplace capabilities, integrations across platforms — to build your own operation on a foundation that actually holds up under volume. Ready to stop duct-taping workflows together? Explore PrintXpand and start building something that scales.